Our Strength Lies On

We have a well-managed factory unit that equips all the required modernized facilities for production of a qualitative range of innovative products.

PTFE bellows are used as balancing elements between engineering parts. They are machined parts. Due to the different geometries of the folds highly flexible or pressure-resistant versions can be designed and manufactured.

PTFE’s outstanding material properties allow bellows to be used increasingly in medical, food and general industrial applications.

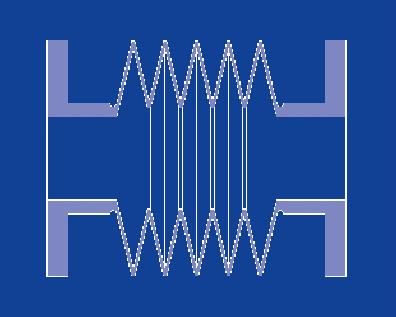

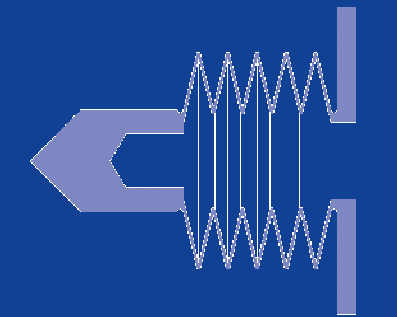

Pointed, Non-cut Folds for maximum expansion and low pressures up to 3 bar.

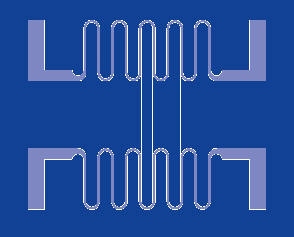

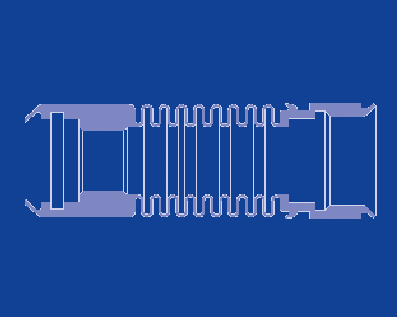

Pointed, Non-cut Folds for maximum expansion and low pressures up to 3 bar. Round, Machined Folds for improved cleaning and maximum reverse bending strength. Low to medium pressures up to 6 bar.

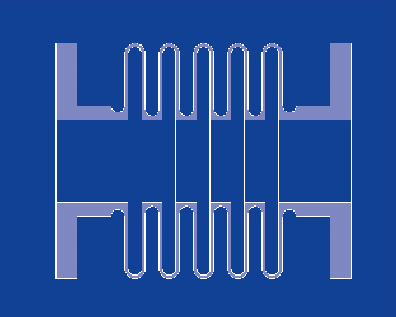

Round, Machined Folds for improved cleaning and maximum reverse bending strength. Low to medium pressures up to 6 bar. Solid, Machined Folds for high pressures above 6 bar. Optimal with rectangular support on the rod or in the cylinder.

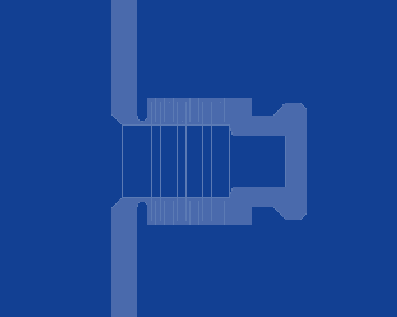

Solid, Machined Folds for high pressures above 6 bar. Optimal with rectangular support on the rod or in the cylinder. Bellows for a solenoid valve in medical technology. High flexibility and frequency. Physiologically harmless. Resistant to aggressive cleaning agents.

Bellows for a solenoid valve in medical technology. High flexibility and frequency. Physiologically harmless. Resistant to aggressive cleaning agents. Bellows for filling valves hermetical separation of the medium from the actuation mechanism. The tip is the sealing cone of the valve.

Bellows for filling valves hermetical separation of the medium from the actuation mechanism. The tip is the sealing cone of the valve. Multi-functional bellows Separation of two areas with moving parts. Integration of sealing and guiding elements. Connections can be performed according to customer specifications.

Multi-functional bellows Separation of two areas with moving parts. Integration of sealing and guiding elements. Connections can be performed according to customer specifications.

We have a well-managed factory unit that equips all the required modernized facilities for production of a qualitative range of innovative products.

To completely satisfy a customer, we mainly focus on the quality level of our in-use working methodology used for developing these offered products.

Our sophisticated infrastructure set-up which is outfitted with modern machines and equipment aids the employees in the smooth execution of the operations.

Fill in your details and

our team will share complete information with you.